Track Sensors

Racing Track Sensors come in all sizes and shapes. Selecting the correct sensor is important as this will help detect the car based on the scale you are racing in. This page will describe each sensor in order below and how each sensor works. Just click on the Highlighted Sensor to be directed to it !

The most used sensors for Slot Car Tracks are the CDS “Phototransistor” module. They are powered from 3-5 vdc and can be adjusted to the light sensitivity. When the sensor is covered by a car or wheel the light is blocked and it sends a signal to the main board activating an effect. This type is mainly used under the tracks surface and a small hole is drilled with the little round CSD cell flush to track.

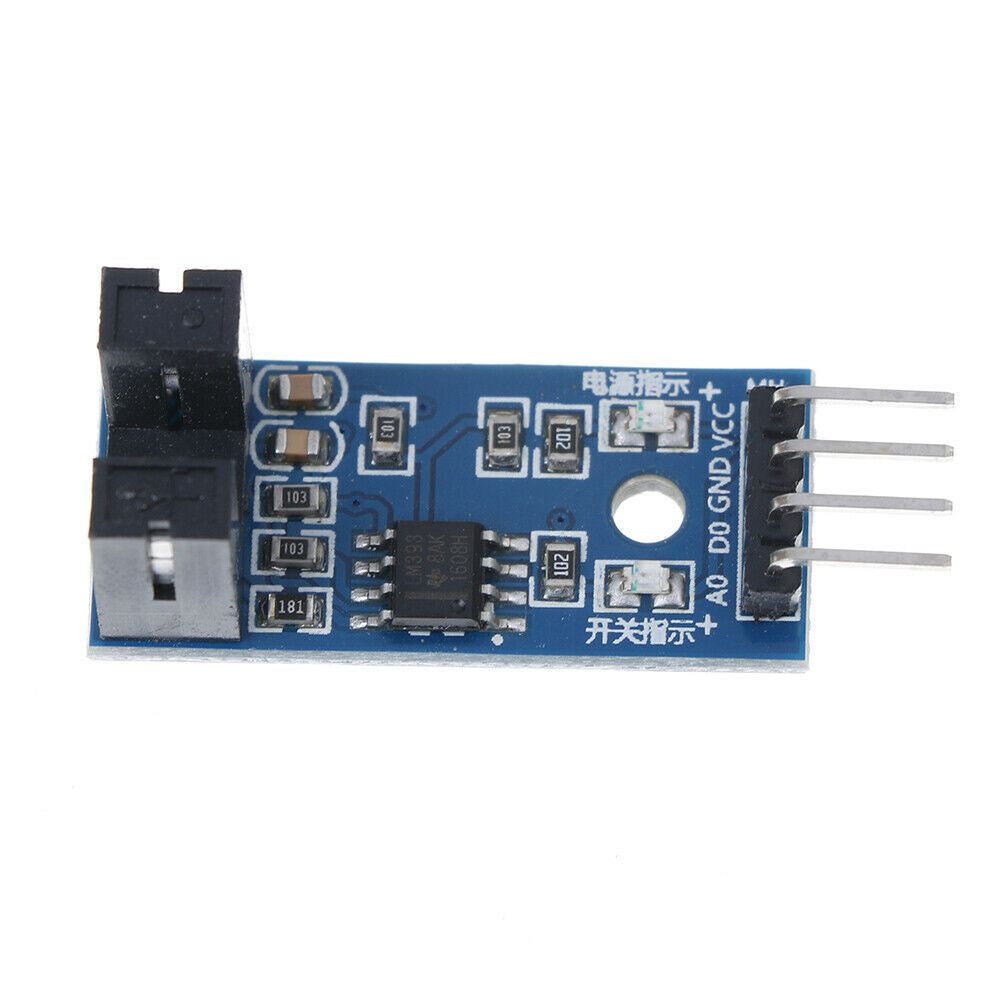

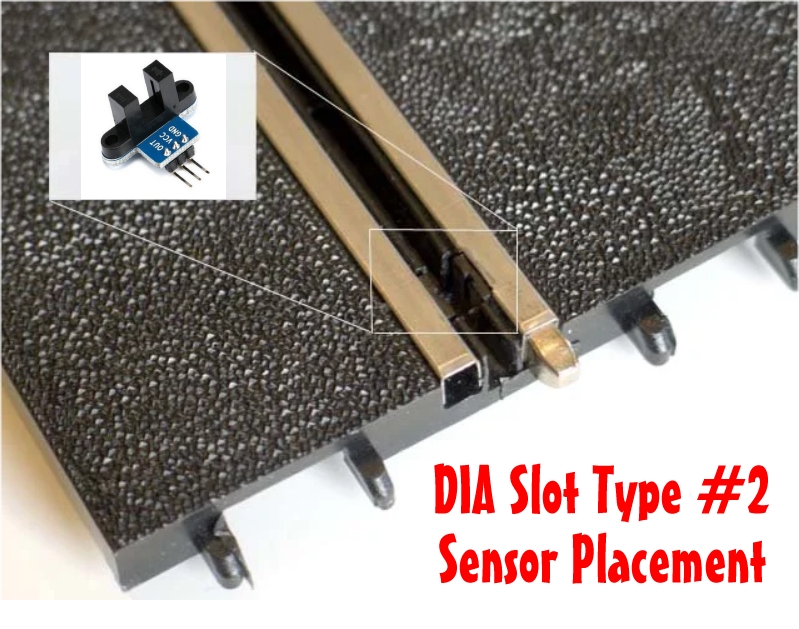

The next type of sensor is the “Slot Type” Photodetector, it also uses from 3-5 vdc and is mounted below the track in the Slot Lane. When the Slot Cars Blade passes this detector the Blade blocks the IR to the Detector and sends a Signal to the main board to count laps or trigger an event. These are mostly used on DIY Club Tracks where you can mount the detector below the layout. A longer Blade is needed on the car to trigger the sensor.

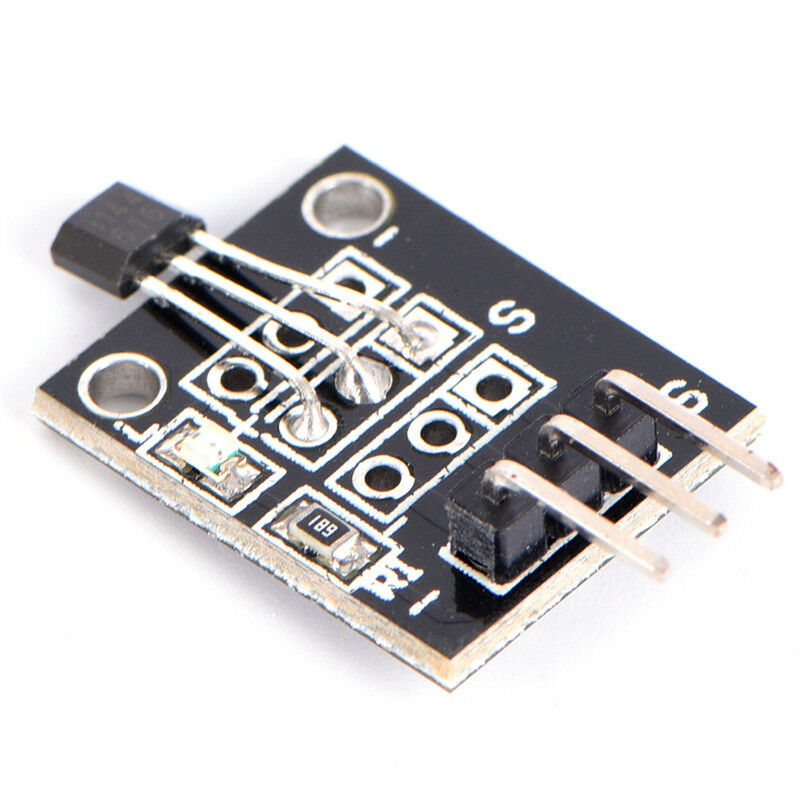

The next type sensor is the “Hall Effect Sensor“. This type contains a small transistor type component that can detect a magnetic field. As the car passes the sensor the it opens a small circuit sending a signal to the main board to activate a result. These run on 5vdc.

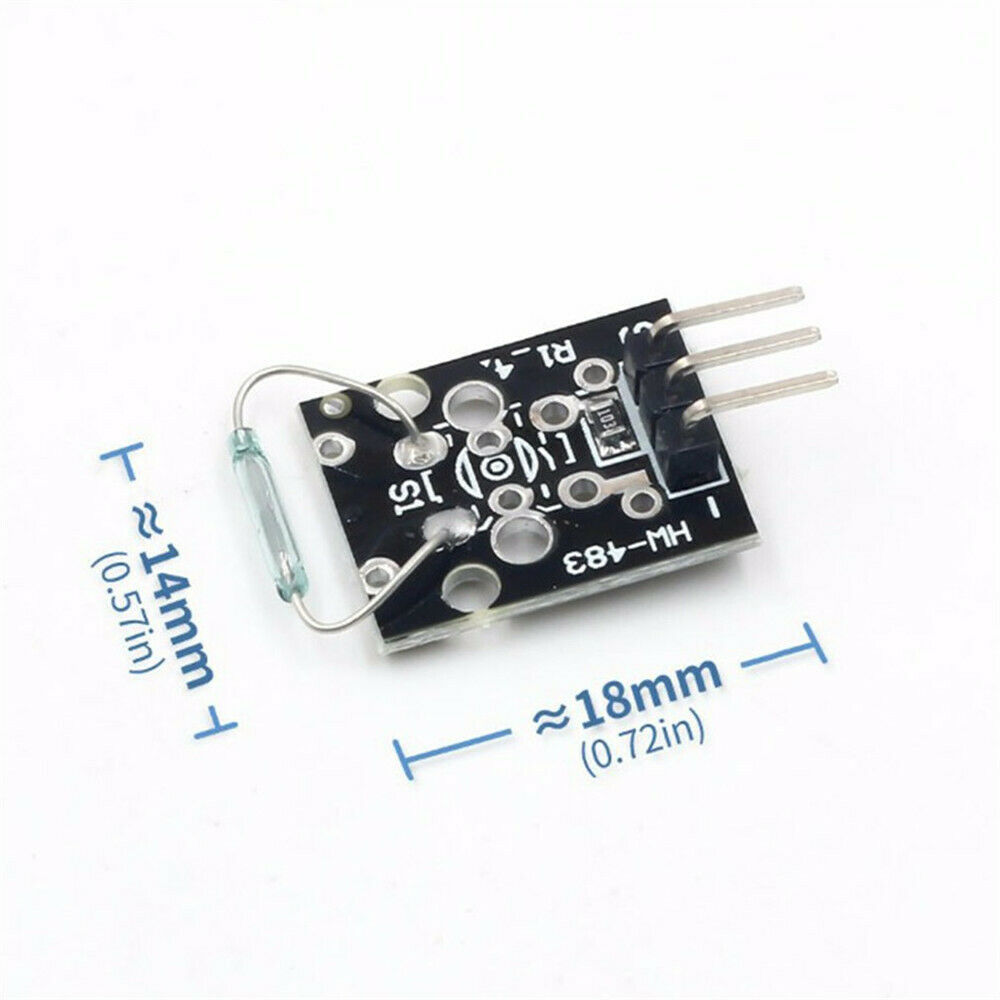

The next Sensor type is the “Magnetic Reed Module“. This small board acts the same way as the Hall Effect board but uses a small reed of metal that when a magnet is passed close to it, the reed is pulled and touches the other reed making a closed contact circuit. Operates on3-5vdc

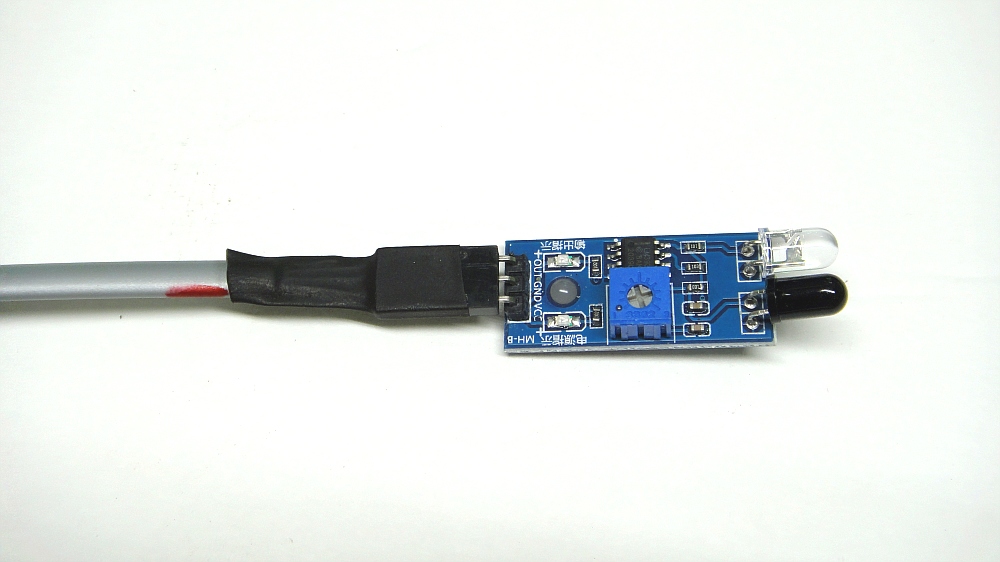

The next in line is our “IR Infrared Module“. This unit can be set under or along side the track to detect a passing car. The sensor can be adjusted from 2 ~ 30cm of detection. It has a IR LED that sends out IR light and when and object reflects back that IR light it is detected by the IR detector LED. Runs on 3-5 vdc and sends out a signal when it detects an object.

The next is not a sensor but a switch, it’s the “Lever Arm Switch”. Being a switch no power is necessary, once an object pass by and presses on the lever arm, it closes or opens the switch. These operate from any voltage ac or dc. How you set them up is up to you.

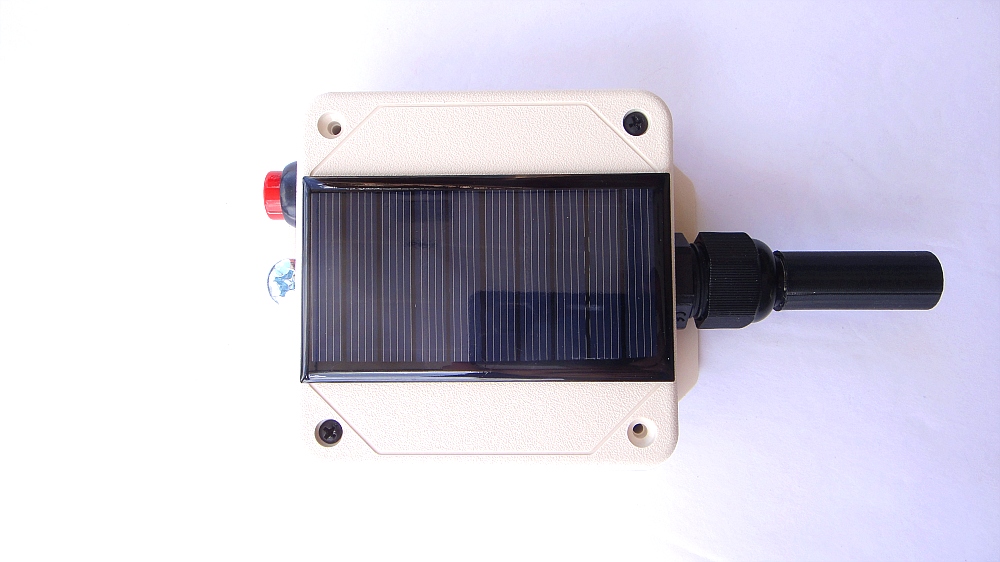

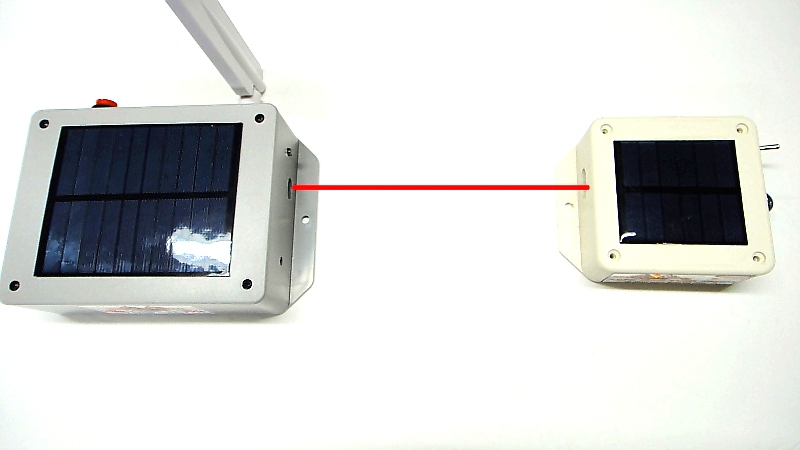

Now its time for the Big Boy Toy Sensors. The “Drag Racing Beam Sensors”. These sensors are what the NHRA® and IRHA® and other Outlaw Track boys use. These send out a LASER or Infrared light that reflects off a beam reflector or is detected by the Laser Detector. You would set the reflector on the center line of the track and the Emitter on the edge of the track. You must adjust the height of the sensor for detecting ether the Tires or Body of Car. They run off 3-5 volt battery power. Once the beam is broken, a “LOW” or Negative signal is sent through a wire or wireless unit back to the main unit. You need 1 set for every location you wish to detect like Start & Finish or Speed traps.

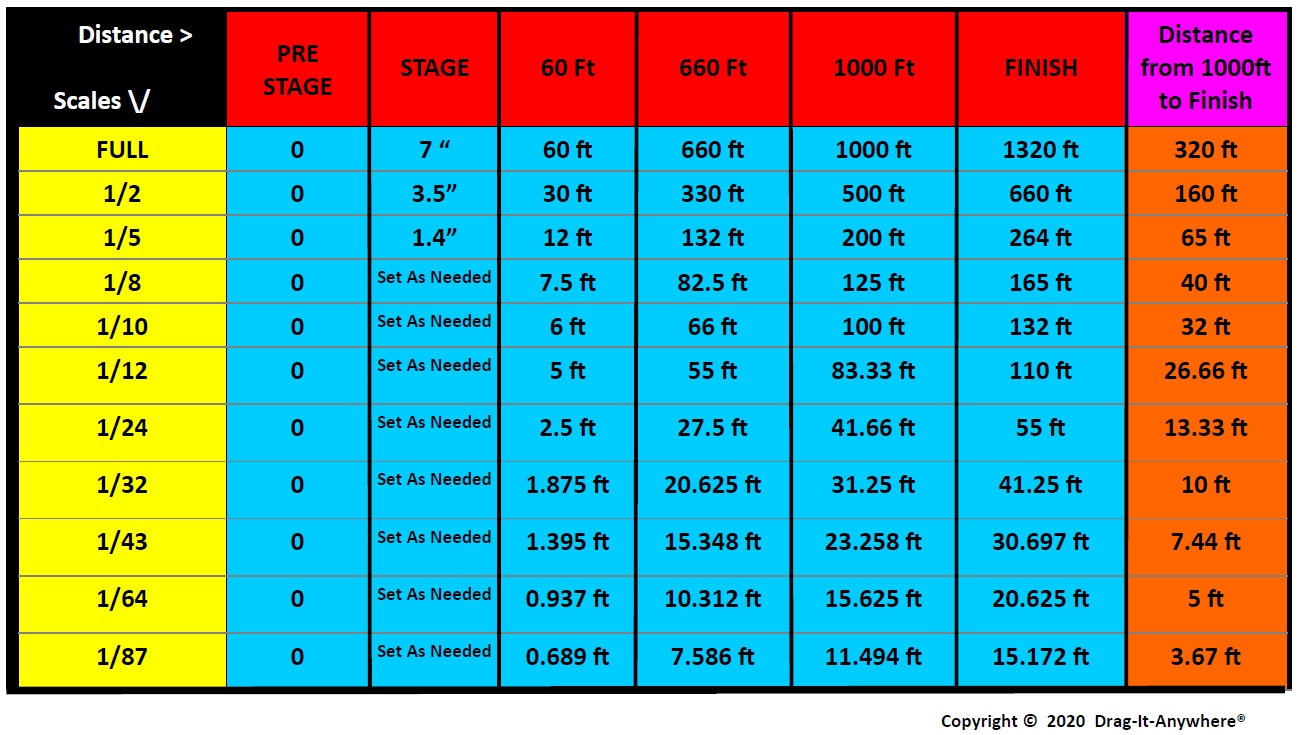

See the Below Chart for Sensor Positions based on your Scale. When running Data cables from DIA unit to Sensor always add 2-3 feet of cable !!

TRACK SENSOR POSITIONS BASED ON SCALE

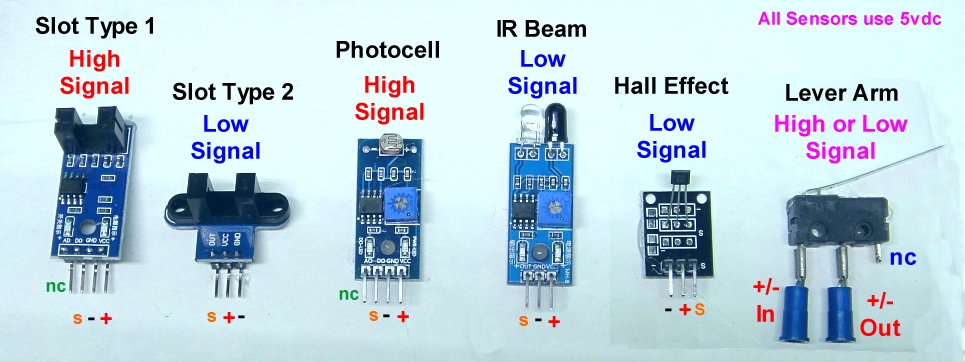

Below is a guide to understand how to connect the sensors with the correct polarity and if you need to set your DIA menu settings for the Sensors to ether HIGH or LOW Detect. A High detect means that the Sensor is outputting a HIGH 5v + voltage until the Sensor is Blocked telling the DIA a car has passed or is covering a Sensor. LOW detect would be a LOW or Negative – Output and is waiting for a HIGH 5v voltage signal to detection a car passing the sensor.

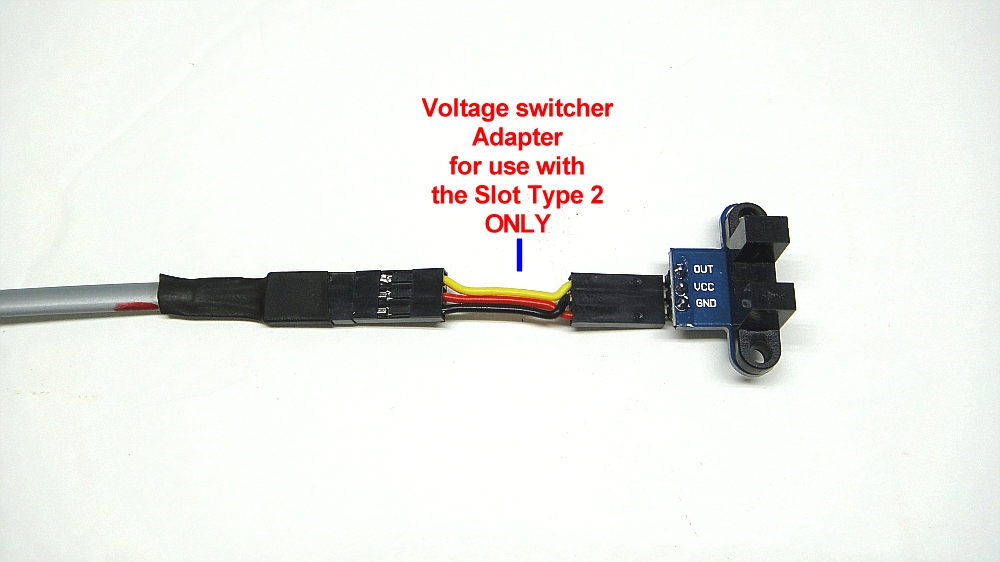

Only the Slot Type 2 will need a Voltage Reverse Adapter so the voltage is connected correctly to that sensors type. If using a Hall Effect, Magnetic Sensor, or a lever Arm switch, you must correctly wire yourself and set DIA to detect HIGH or LOW as needed.

You can MIX sensors so long as they have the same HIGH or LOW outputs, so a Slot Type 1 can be used with a Photocell sensor.

For correct positioning of the Sensors please see our Start & Finish Display page.

SENSOR TYPES

Slot Type #1 Track Sensor 5v. This sensor is placed in the Tracks slot and the Cars Blade will block the light triggering the sensor. Great for any conditions it needs no light. It is a bit tricky to get set right, and if your running a car with a short blade it may not detect it!

Slot Type #2 Sensor 5v. Same as #1 but smaller and circuit board is on back side. The +/-/S is also reversed so you have to use adapter.

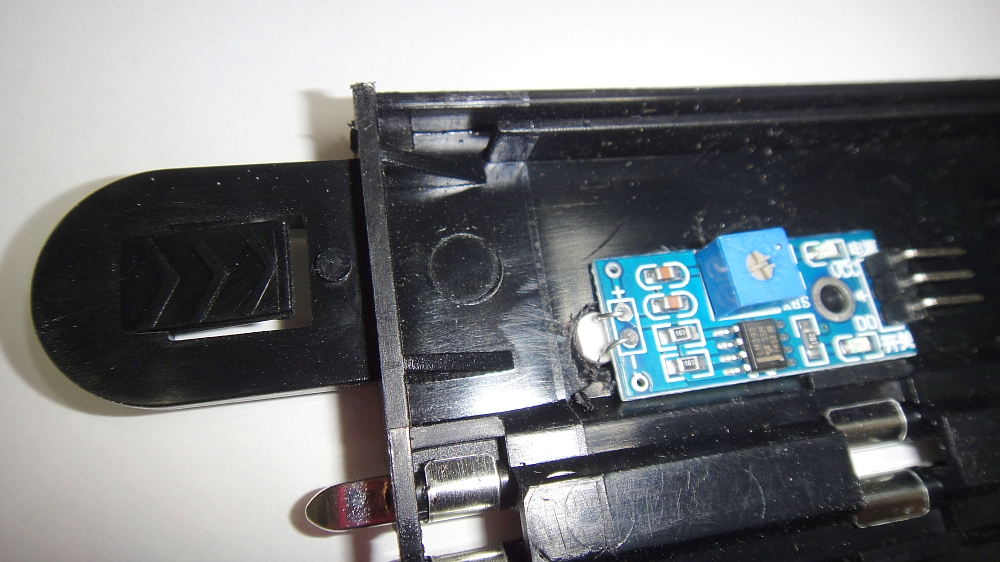

Photoresistor Type Sensor 3-5v. This is the Most used sensor for all slot car tracks as it can be placed in many places. Mostly set under track near slot.

IR 5v Sensor for Side and Up Sensing. Used mostly were light conditions change a lot and are not constant. Use for 1/32, 1/24 scale for Side Slot Detection.

IR Beam 12v, used for 1/12, 1/10 and up scale. Good for up to 10 feet out on track. Comes with Solar panel charging system.

IR Laser Beam Sensor and Detector 12v. This detection system is used for scales like 1/10 and up even to full scale cars and objects. The Beam is an IR laser that is good out to 80ft from detector, comes with Solar panel to keep the Beam charged at all times. The Detector comes in both a Wired and Wireless version.

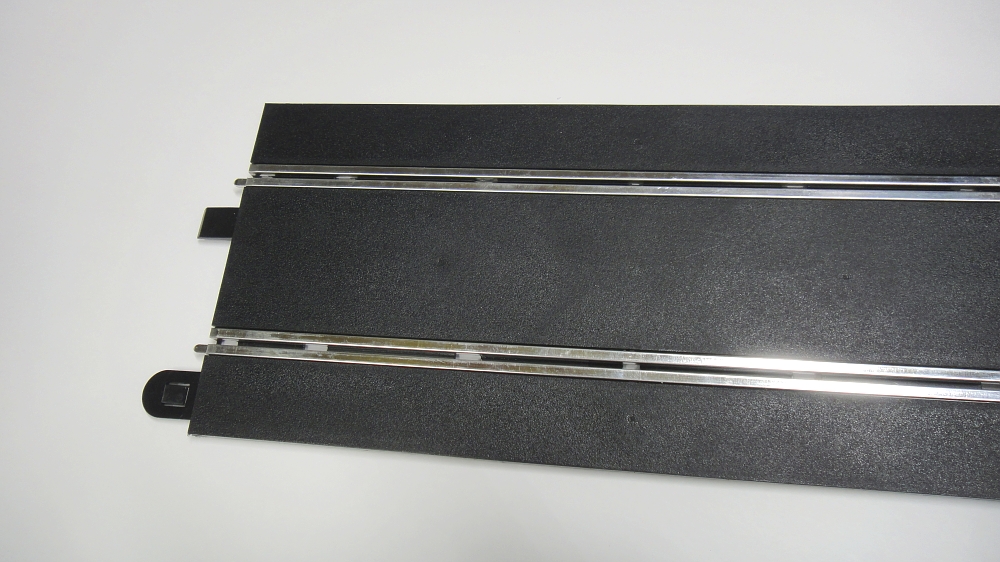

For useing our Slot Type #1 and # 2 you must cut a slot in the track to allow the Slot Type to fit flush to the Track Brade or metal. Check to make sure your Cars Blade is not to long and it must slide thru the detectors smoothly.

TRACK SENSOR PLACEMENTS

Below are examples of where to place your track sensor for reliable detection. Still its up to the track builder to find the best location based on your Scale and style of racing.

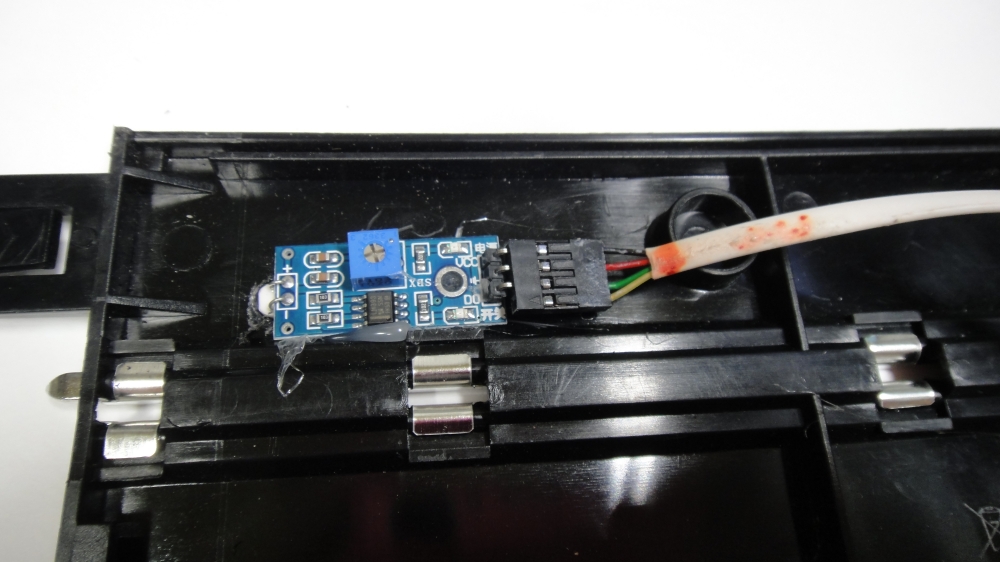

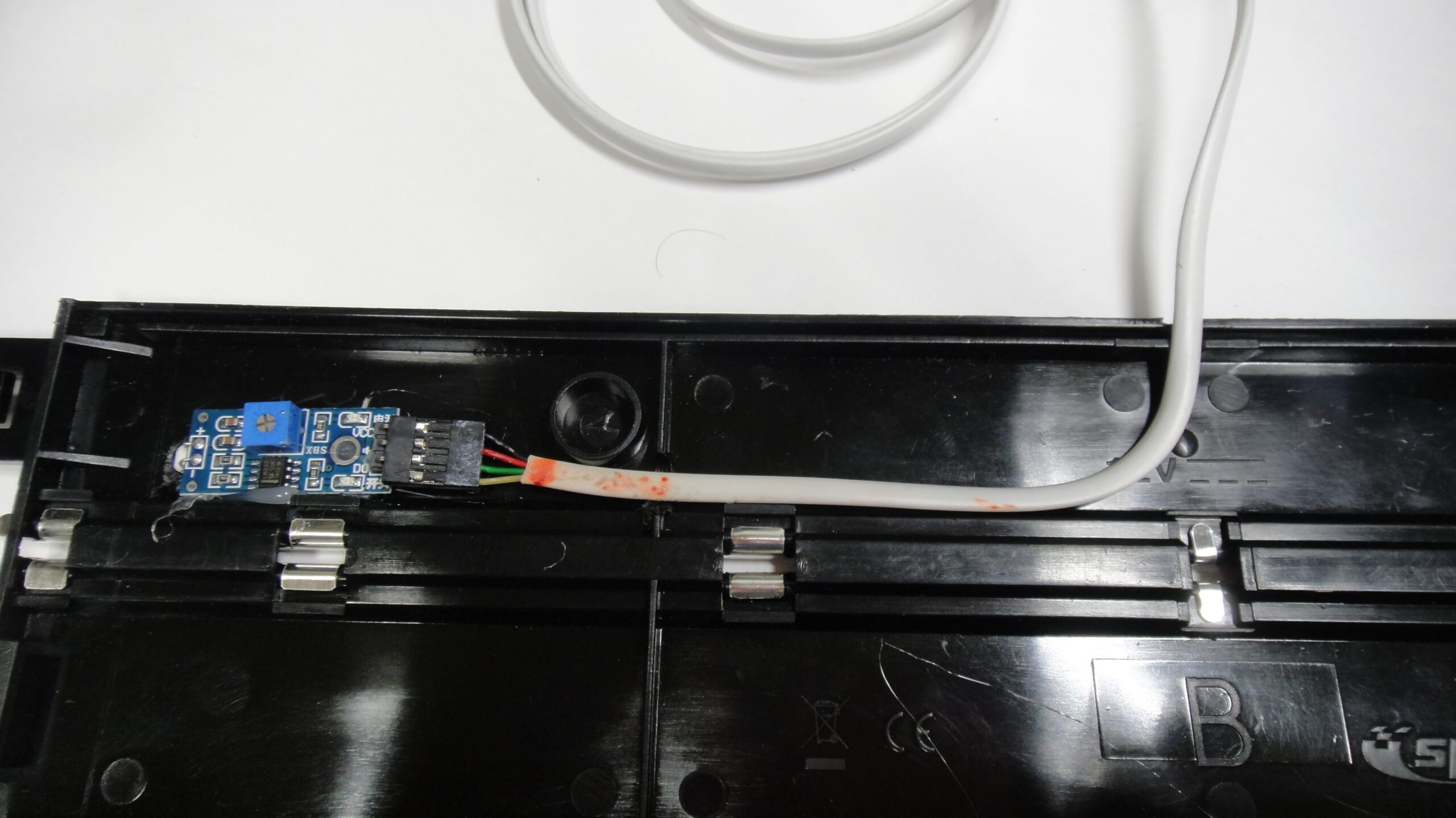

Example of Photoresistor Sensor installed in a Scalextric Track.

Select position you wish to set the Sensor. I like to set close and tight to slot.

I find it best to use a Dremel and make a small hole to fit the sensor tight.

Test fit sensor and make sure its not to close to the center rail edge.

Fit Photocell into hole and drill out as needed to make a tight fit.

Push sensor flush with track top so it will not effect the car tire performance.

Use hot glue to set Sensor in place. Push but make sure Photocell is flush to track surface.

Connect the Dupont 3-pin Data cable to Sensor and run other end to Drag It Anywhere Timing System

Run Data cable as needed under or along side of track back to DIA unit. In some cases you may have to set track on spacer as the Sensors will not always be flush to track bottom. Happy Racing Boys !!!!